A quasi-cw laser source is a type of laser that generates a continuous wave of light with a relatively long pulse duration compared to other lasers. These lasers are often used in scientific and industrial applications where a stable, continuous beam of light is required.

Table of Contents

What is it?

Quasi-CW lasers differ from traditional continuous wave (CW) lasers in that they have a slightly longer pulse duration, typically on the order of microseconds or milliseconds. This longer pulse duration allows for a more stable and consistent output of light, making them ideal for applications that require a steady beam of light over an extended period of time.

One of the primary advantages of quasi-CW lasers is their ability to produce a beam of light with a high degree of spatial and temporal coherence. This means that the light waves are all in phase with one another and are highly directional, resulting in a beam of light that is both highly focused and highly collimated. This makes them ideal for a wide range of applications, including laser scanning, laser printing, and laser machining.

There are several different types of quasi-CW lasers, including solid-state lasers, fiber lasers, and gas lasers.

Solid-state Lasers

It is the most common type of quasi-CW laser and is made from solid materials such as crystals or glasses. They are highly efficient and have a long lifetime, making them a popular choice for many applications.

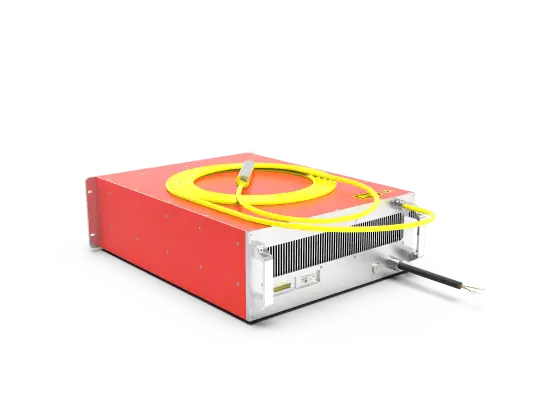

Fiber Lasers

A type of quasi-CW laser that use fibers to guide the light and generate the laser beam. These lasers are highly efficient and are often used in high-power applications such as cutting and welding.

Gas Lasers

These are the third type of quasi-CW laser and are made from gases such as helium, neon, or argon. These lasers are highly efficient and are often used in applications where a high-power beam is required.

In summary, quasi-CW laser sources are a type of laser that generates a continuous wave of light with a relatively long pulse duration. They are highly efficient, reliable, and ideal for a wide range of scientific and industrial applications due to their high degree of spatial and temporal coherence.

Also, Check – How Do Injection Molding Machines Work?

Advantages of Quasi-CW laser Sources:

The high degree of spatial and temporal coherence: Quasi-CW lasers produce a beam of light that is highly focused and collimated, making them ideal for a wide range of applications such as laser scanning, laser printing, and laser machining.

Efficiency and reliability: Quasi-CW lasers are highly efficient and reliable, making them a popular choice for many scientific and industrial applications.

Long lifetime: Quasi-CW lasers have a long lifetime, making them a cost-effective choice for applications that require a continuous beam of light over an extended period of time.

Wide range of applications: Quasi-CW lasers can be used in a variety of scientific and industrial applications, including material testing, cutting and welding, and laser printing.

Versatility: There are several different types of quasi-CW lasers available, including solid-state lasers, fiber lasers, and gas lasers, allowing for a wide range of options to suit different applications.

High power output: Quasi-CW lasers can produce a high-power beam of light, making them ideal for applications such as cutting and welding.

Precision: Quasi-CW lasers are highly precise, allowing for precise cutting and drilling of materials.

Non-contact processing: Quasi-CW lasers can be used for the non-contact processing of materials, making them ideal for delicate or sensitive materials.

Speed: Quasi-CW lasers can process materials at high speeds, making them ideal for high-production environments.

Safety: Quasi-CW lasers are generally safer to use than other types of lasers due to their low power output.

Precautions When Using Quasi-CW laser Sources:

Eye protection: It is important to wear proper eye protection when working with quasi-CW lasers to protect against potential eye damage.

Laser safety regulations: Quasi-CW lasers are regulated by laser safety standards, and it is important to adhere to these standards to ensure safe operation.

Proper handling: Quasi-CW lasers should be handled carefully to prevent accidental injury or damage to the laser.

Maintenance: Quasi-CW lasers require regular maintenance to ensure they are operating safely and efficiently. Training: It is important for operators to receive proper training in the use of quasi-CW lasers to ensure safe and effective operation.